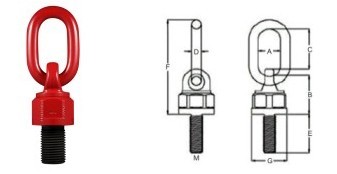

产品原料选用最好的AISI航空质量级铬钼合金钢,经过分光仪材质分析和认证,确保元素成份的正确,严格按照MIL-H-6875热处理和ASME规定100%磁粉探伤检查,经过调质,具有非常稳定的抗疲劳性能,螺栓强度可达到12.9级,精度6g,螺纹杆表面经过发黑防锈处理,产品严格按照欧盟EN1677生产检验,以1.5倍的安全载荷,施以20,000次动态疲劳试验及静态4倍极限破断拉力实验,确保产品热理工程的强度及韧度。产品直拉侧拉均可,适用于风电,模具,机床等设备的起重提升。

|

螺纹型号Diameter |

载荷WLL(kg) |

参数 (mm) |

重量weight |

|

A |

B |

C |

D |

E |

F |

G |

|

M8X1.25-6g |

400 |

28.6 |

39.0 |

31.8 |

7.90 |

12.0 |

85.8 |

36.0 |

0.27 |

|

M10X1.5-6g |

500 |

28.6 |

39.0 |

31.8 |

7.90 |

19.0 |

85.8 |

36.0 |

0.27 |

|

M12X1.75-6g |

1050 |

35.0 |

67.0 |

58.0 |

12.7 |

19.1 |

149.8 |

60.0 |

1.20 |

|

M14X2.0-6g |

1150 |

35.0 |

67.0 |

58.0 |

12.7 |

31.8 |

149.8 |

60.0 |

1.20 |

|

M16X2.0-6g |

1900 |

35.0 |

67.0 |

58.0 |

12.7 |

31.8 |

149.8 |

60.0 |

1.20 |

|

M20X2.5-6g |

2150 |

40.0 |

78.3 |

67.0 |

19.1 |

38.1 |

178.7 |

70.0 |

2.21 |

|

M22X2.5-6g |

2250 |

40.0 |

78.3 |

67.0 |

19.1 |

38.1 |

178.7 |

70.0 |

2.21 |

|

M24X3.0-6g |

1200 |

40.0 |

78.3 |

67.0 |

19.1 |

38.1 |

178.7 |

70.0 |

2.21 |

|

M30X3.5-6g |

5000 |

51.6 |

93.1 |

95.0 |

22.2 |

50.0 |

227.4 |

80.0 |

386 |

|

M33X3.5-6g |

7000 |

51.6 |

93.1 |

95.0 |

22.2 |

50.0 |

227.4 |

80.0 |

3.86 |

|

M36X4.0-6g |

8000 |

51.6 |

93.1 |

95.0 |

22.2 |

54.0 |

227.4 |

80.0 |

3.86 |

|

M39X4.0-6g |

8000 |

51.6 |

93.1 |

95.0 |

22.2 |

58.0 |

227.4 |

80.0 |

3.86 |

|

M42X4.5-6g |

10000 |

65.0 |

103.7 |

118 |

25.0 |

63.0 |

265.8 |

93.0 |

6.08 |

|

M45X4.5-6g |

10000 |

65.0 |

103.7 |

118 |

25.0 |

68.0 |

265.8 |

93.0 |

6.08 |

|

M48X5.0-6g |

10000 |

65.0 |

103.7 |

118 |

25.0 |

68.0 |

265.8 |

93.0 |

6.08 |

|

M56X5.5-6g |

15000 |

70.0 |

134.9 |

120 |

32.0 |

84.0 |

309.3 |

105 |

10.8 |

|

M60X5.5-6g |

15000 |

70.0 |

134.9 |

120 |

32.0 |

90.0 |

309.3 |

105 |

10.8 |

|

M64X6.0-6g |

15000 |

70.0 |

134.9 |

120 |

32.0 |

95.0 |

309.3 |

105 |

10.8 |

|

M72X6.0-6g |

25000 |

80.0 |

166 |

125 |

40.0 |

108.0 |

371.0 |

130 |

25 |

|

M80X6.0-6g |

30000 |

80.0 |

166 |

125 |

40.0 |

120.0 |

371.0 |

130 |

27 |

|

M90X6.0-6g |

35000 |

80.0 |

166 |

125 |

40.0 |

135.0 |

371.0 |

130 |

30 |